Aviation Old Tom Gin Southern

$ 40,00 $ 24,00

42% ABV, 750ml

PRODUCTION

Every bottle of Aviation Gin is handcrafted in small 100-case batches at the House Spirits Distillery in Portland, Oregon by master distiller Christian Krogstad and Andrew Tice.

Like the world’s finest gins, Aviation is distilled using a proprietary maceration process that produces a pure medley of botanical flavor.

STEP 1: INFUSION

It all starts with our precise blend of botanicals, sourced from around the world – cardamom, coriander, French lavender, anise seed, sarsaparilla, juniper, and two kinds of orange peel. The botanicals are placed in nylon sacks and suspended in a pure, neutral grain spirit for 18 hours in macerating tanks.

STEP 2: DISTILLATION

The macerate is then pumped into a stainless steel still along with pure water. Steam jackets heat the macerate, the vapors go into a shotgun condenser, come into contact with the cold water, and the distillate forms.

STEP 3: THE CUT

In a meticulously monitored process, the first fluid leaving the still, the “heads,” is removed. Collecting the “heart of the spirit” throughout the run, the distillers then determine the end of the cycle and make the final cut, “the tails.” This process takes approximately 7 hours and at this point, the “heart cut” is 142 proof.

STEP 4: BLENDING & BOTTLING

The “heart cut” is transferred to a blending tank where pure water is added, bringing the gin to the desired 84 proof. It then goes into a bottling tank with a 6-sprout gravity filler and pumped into bottles. Labels, caps, and cap strips are all applied by hand. A craft production from beginning to end, Aviation is then ready to pack and ship.

Fast Delivery and Professional Packaging

Our long-standing partnership with UPS FedEx DHL and other carriers around the world lets us offer a range of shipping services. Our warehouse employees will pack each item according to our strict requirements. Prior to shipping, your goods are carefully examined and securely secured. We ship to thousands of customers each day across different countries. This is a testament to our commitment to be the biggest online retailer in the world. Warehouses and distribution centers are located throughout Europe as well as in the USA.

Orders with more than 1 item are assigned processing periods for each item.

Before shipping, all ordered items will be thoroughly examined. Currently, most orders are shipped within 48 hours. Delivery time ranges between 3-7 days.

Returns

The stock is constantly changing. It's not completely managed by us, as we're involved with several organizations, such as the factory and the storage. So the actual stock may alter at any time. Please be aware it's possible your order could run out of stocks once you've placed your order.

The policy is 30 days. If 30 days have gone without a trace since the purchase, unfortunately we can't offer an exchange or refund.

The item should not be in use and must be in the original packaging. The item should be returned in its original packaging.

Related products

SPIRITS

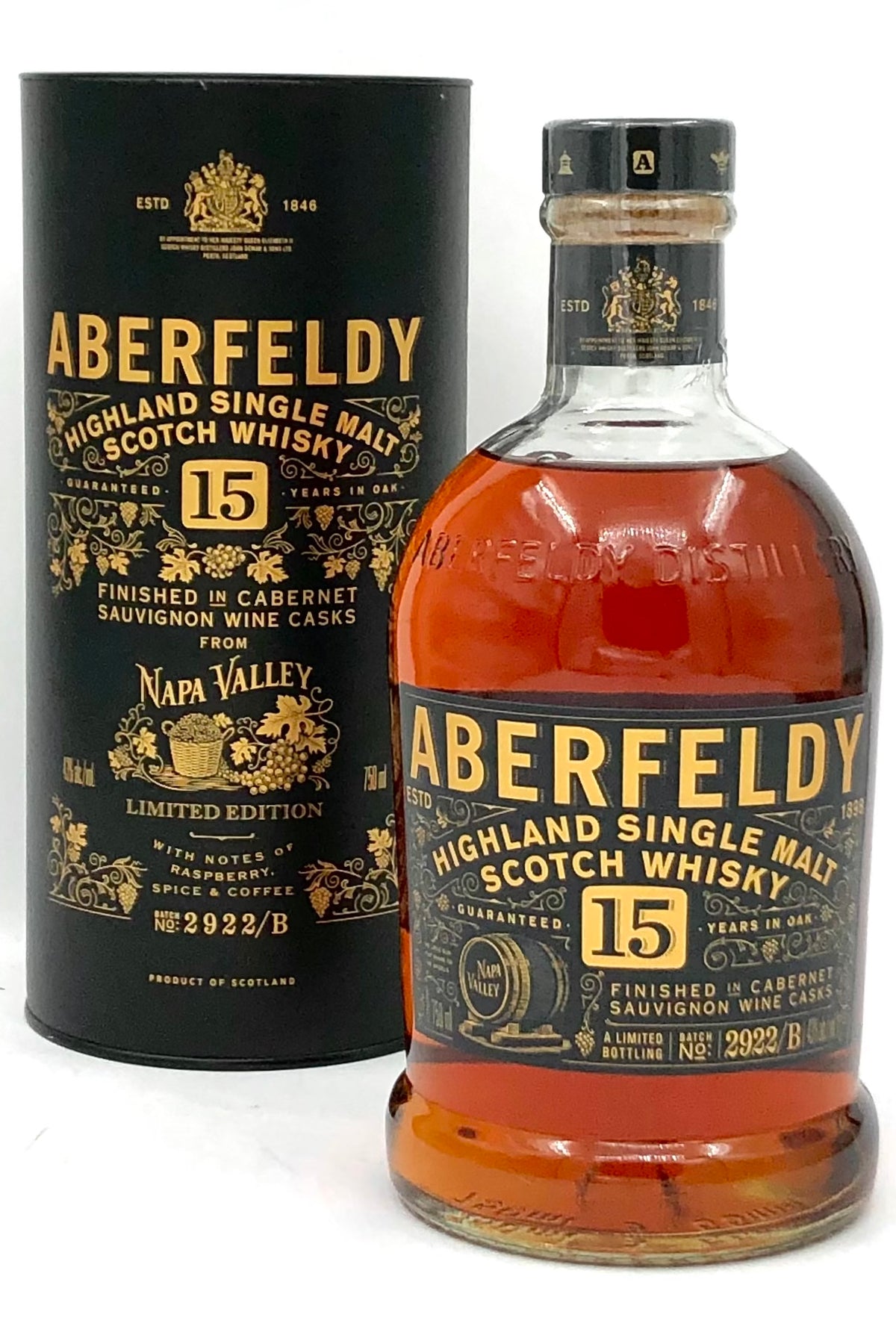

SPIRITS

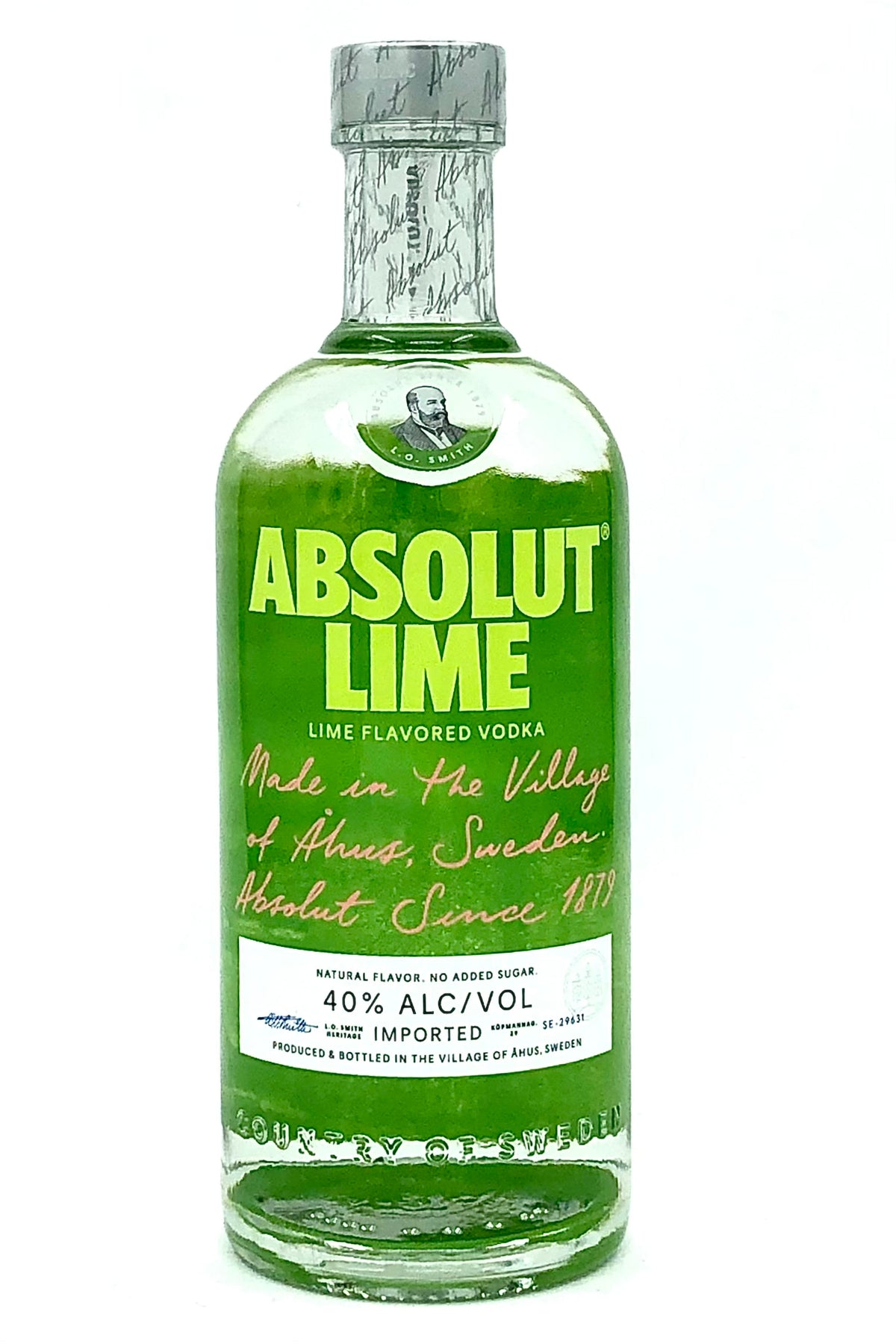

SPIRITS

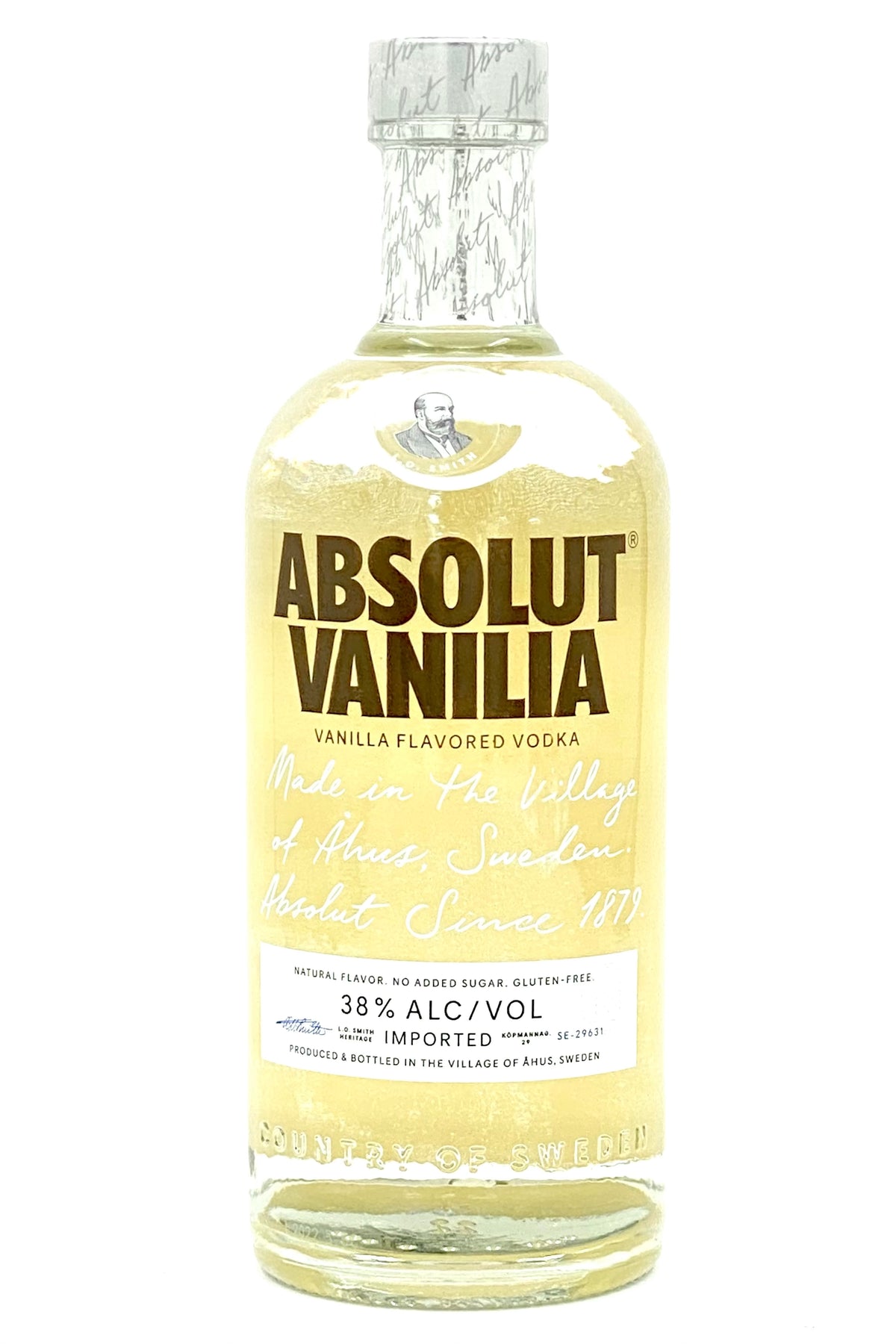

SPIRITS

SPIRITS